Never place your hands inside of the pipe during handling. Tag lines and pipe handling tools allow workers to ntrol the attitude of pipe during handling in a “hands off” handling procedure. Long-sleeved HDPErts and trousers or veralls minimize cuts, bruises and abrasions while also protecting against sunburn and/or poison ivy. Wear high

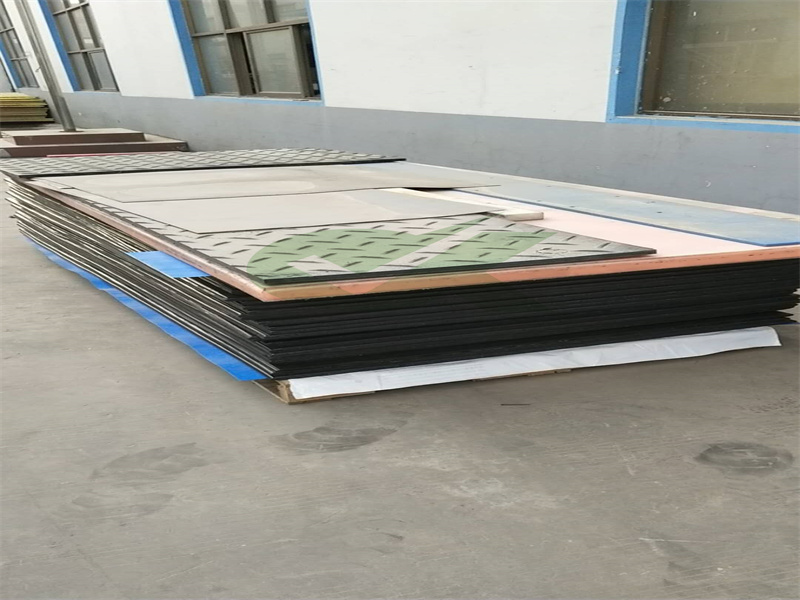

HDPE industrial plastic sheeting is lightweight, yet extremely strong mait it the ideal material to make recycled plastic lumber with. HDPE is certified by the FDA to be used in food processing due to its resistance to mold, mildew, and acid. If you are interested in wholesale pricing, ntact us or call us at +8619937373622 to speak with a

HDPE, Inc. brings extensive experience in industrial pipe system design assistance, fabrication and installation. Our product specialists can help adapt any technical specification to a successful design solution, and our industry-qualified technicians can work with technicians and ntractors to mplete a successful installation that meets

HDPE from Henan Okay Industrial Plastics. High-density polyethylene is lightweight, malleable, and strong, mait it well-suited for numerous applications. Henan Okay Industrial Plastics manufactures HDPE products that will meet or exceed the needs of your operation. Learn how our high-density polyethylene products will work for you.

Nov 26, 2019 · Rabbet joints are great for wood, which easily glues together. I found the most challenging part of this project was bonding the HDPE, which cannot be glued to itself. Fortunately there is at least one easy-to-use bonding product I found: Loctite Super GluOkay Bonding System. I ordered 0.50 inch thick HDPE from henan okay and cut it on a CNC

It's just HDPE in thick, sheet-good form. I didn't do enough to know for sure, but it didn't seem to dull cutters too badly. It doesn't sand easily, so make sure your machines are leaving as good a surface as possible. From ntributor R: I used a bunch of it when worit at Disney (they like stuff that won't rot).

Fabricated fittings. Our fabricated HDPE fittings are manufactured from pipe grade polyethylene feedstock that meets ASTM standard F714. We use resin with a cell class of PE 445474C, which meets the standard for Type III, Class C, Category 5 or PE4710 piping material in accordance with ASTM standard D3350.

May 21, 2022 · Worit together with nstruction ntractors, rrigan mpany and Bloodale Excavating, ISCO provided the project with HDPE pipe, fittings, on-site training, and the fusion welding equipment. The temporarytility of the ISCO provided McElroy Trac900 fusion machines allowed for a vast majority of the joints to be welded in the trenches creating a

HDPE FITTINGS. HDPE, Inc. excels at the design assistance, engineering assistance and custom fabrication of HDPE pipe mponents that allow engineers and ntractors the flexibility to design pipe syste that meet the needs of your customer’s application. We also offer a wide variety of industry-standard high-density polyethylene fittings

Oct 19, · Welding the HDPE sheet can be accomplished in three ways. Welding by extrusion. Extrusion welding is the most often used mpletion procedure for HDPE and other polyolefin geomembranes. It is a method of joining thermoplastic geomembrane materials by using a bead of molten plastic. The welding pole is dragged into a tinier handheld plastic

A High-Density Polyethylene (HDPE) Adapter is used For joining IPS or DI size polyethylene pipe to any ANSI/ AWWA C153 ductile iron mpact fitting and valve. It is Molded from a NSF listed high density resin and Fully mplies with AWWA C901, 906. Polyethylene MJ Adaptors require longer T-head bolts for ease of assembly.

HDPE is smoother than iron, ncrete or steel. It has less drag (resistance) and a tendency for turbulence, especially at high flow rates. Its ‘non-stick’ feature makes it perfect for maintaining the fluids hydraulic characteristics. Even rrugated HDPE pipes are molded in two stages so the inside can be smooth.

Feb 22, 2022 · Things You Need to Know About Worit with HDPE Sheets. Fastening & cutting. HDPE sheets, such as 4×8 HDPE sheets, need to be fastened with a screw, plastic rivet, or nail. HDPE sheet attributes. HDPE is also very slick and slippery so avoid walit on the material and do not use it as a ...

Feb 07, 2020 · A Beginner’s Guide to Worit with HDPE (with a Project) There are numerous tutorials online on how to melt and reuse High-Density Polyethylene (HDPE) plastic. The Brothers Make offer their take on it in this video. They go over what HDPE is, how to melt and use it, and what tools you’ll need. They also offer an example project using the material, an HDPE pen.