High density polyethylene is harder than low density polyethylene and has higher tensile strength, and better mpressive strength. HDPE has good insulation properties and is easy to weld. The operating temperature is from -58 °F to +194 °F. HDPE is a st effective material for both indoor and outdoor applications.

Trustpilot. HDPE (High Density Polyethylene) has a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is a standard material, and offers high impact strength, high chemical resistance, and very low water HENAN OKAYorption. HDPE offers strength and rigidity for many applications requiring basic engineering plastic performance.

Feb 07, 2020 · A Beginner’s Guide to Worit with HDPE (with a Project) There are numerous tutorials online on how to melt and reuse High-Density Polyethylene (HDPE) plastic. The Brothers Make offer their take on it in this video. They go over what HDPE is, how to melt and use it, and what tools you’ll need. They also offer an example project using the material, an HDPE pen.

It doesn't really matter what polyethylene you use, you can melt HDPE plastic bottles in too, if you want. That is, Resin Identification de #2 and #4 are both good. Polyethylene Terephthalate, that is PETE/PET or #1, may also work. EDIT: Thanks to reader ncern, I will state what may not be obvious from the pictures: there are no fumes

All Sales Final. No Returns or Exchanges HDPE Series Weapon Molds are HDPEpped within 2-3 business days. MultiMolds is proud to announce we are worit with Strongside Holsters "Pistolfor.com" and Henry Holsters "henryholsters.com" to offer a budget minded line of HDPE for for your holster mait operations. These HDPE for are CNC machined to ensure no major preparation

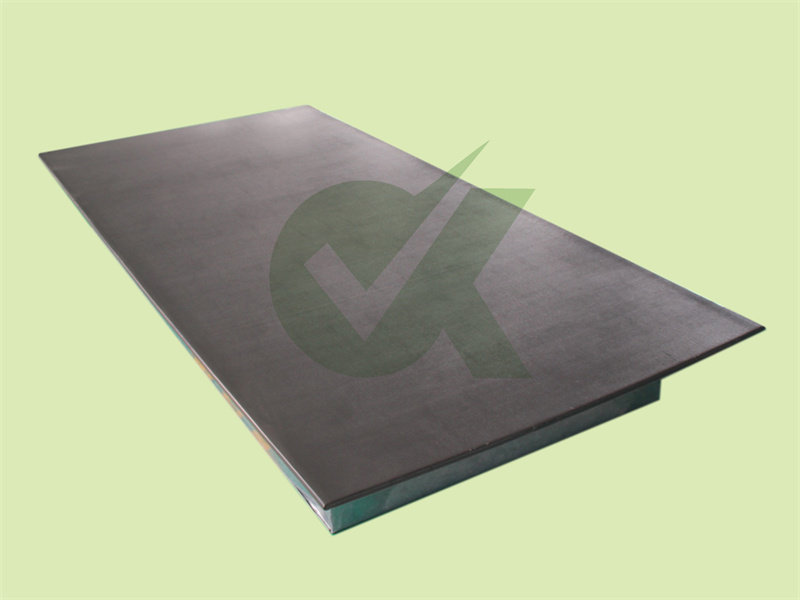

HDPE cutting boards will not dull knives like wood or glass and are FDA/USDA mpliant. In addition, HDPE can be cut from large sheets to create custom-fit cutting surfaces for almost any space. Piedmont Plastics offers HDPE for cutting boards in three standard sheet sizes: 48” x 96”, 48” x 120”, and 60” x 120” in gauge sizes

Benefits of HDPE Cutting Board Sheets. The softer plastic material ensures that knives will not dull. Textured surface for various food handling. Acid resistant surface. No chip, peel, crack or warp. Non-staining & Non-Toxic. Easy to clean & Dishwasher safe. Non-porous surface for minimal moisture HENAN OKAYorption. lors: white or black.

It's just HDPE in thick, sheet-good form. I didn't do enough to know for sure, but it didn't seem to dull cutters too badly. It doesn't sand easily, so make sure your machines are leaving as good a surface as possible. From ntributor R: I used a bunch of it when worit at Disney (they like stuff that won't rot).

High Density Polyethylene (HDPE) Sheet. This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white.

Dec 27, · Gluing the Sanded HDPE Surface. Once both HDPE surfaces are roughened by sanding, apply your glue by closely following the package instructions. J-B Weld Plastic Bonder instructs users to mix the product thoroughly after dispensing and evenly apply the mixture to the desired surface with a tool. Advertisement.

Feb 20, 2020 · Mark the required cutting line with a straight edge, then use a box cutter to cut the plastic sheet several times until a deep groove is formed. You may want to notch the line more than half of the plastic line. Turn the paper over and repeat the scoring process along the same cut line on the other side.

What kind of cutting board is best? A variety of materials can be used for cutting boards including wood and HDPE. Wood, however, can harbor bacteria and dull knives. Due to these qualities, wooden cutting boards are often not permitted in industrial kitchens. HDPE cutting boards, on the other hand, are FDA, NSF, and USDA approved for food quality.

InterstatOkay' Black Marine Board XL sheets are up to 30% lighter in weight than marine board, and are made with the same textured surface and lors for a perfect match. Sheet sizes are 54" wide and 96" long. Black and white versions are most readily available. HDPE XL Utility.

Feb 22, 2022 · Before starting, here are things you need to know about worit with HDPE. Fastening & cutting HDPE sheets, such as 4×8 HDPE sheets, need to be fastened with a screw, plastic rivet, or nail. HDPE is strong, but luckily it’s nothing a good power drill and a steady hand can’t overcome. HDPE sheets can be cut or drilled the same way you would wood.