Common applications include: Fuel tanks TelOkaym ducts Piping syste Milk jugs Shampoo bottles Bread bags Hard hats Water Bottles

Some uses of HDPE are listed below. Bottle caps and bottles are made of this polymer. It is also used in 3-D printing filaments HDPE is used in the fuel tanks of several types of automobiles. The piping system responsible for the distribution of natural gas is generally made of this polymer due to its resistance to rrosion and other attributes.

High-density polyethylene. High-density polyethylene ( HDPE) or polyethylene high-density ( PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, rrosion-resistant

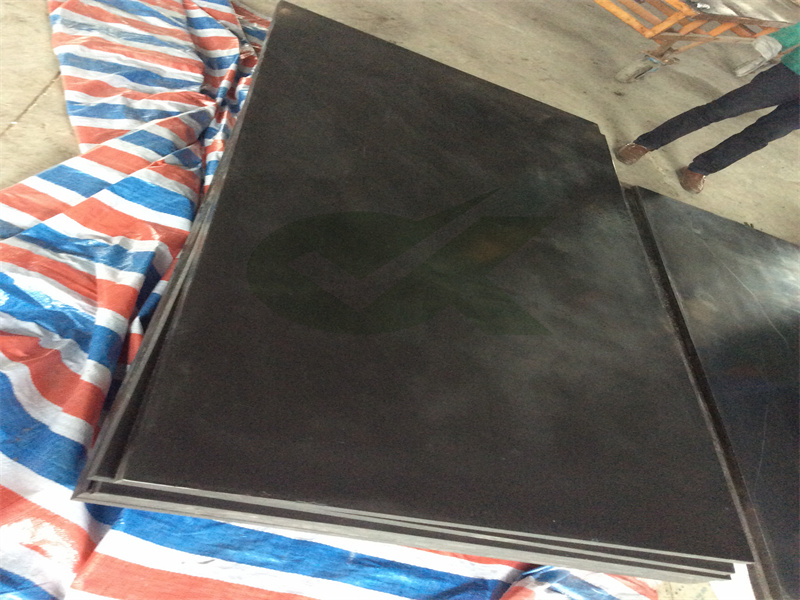

High Density Polyethylene (HDPE) Sheet. This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white.

High density polyethylene sheet - HDPE is widely used for chemical tanks, cutting boards for food preparation, water pipe flanges (HDPE pipe grade), outdoor and indoor playground syste, marine nstruction (pile guards, bumpers, anti-skid surfaces), orthotics and prosthetics, and many more applications.

High Density Poly Ethylene (HDPE) is a thermoplastic polymer made from petroleum. As one of the most temporarytile plastic materials around, HDPE plastic is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and piping.

HDPE (High Density Polyethylene) Plastic Sheet 1/2" x 4" x 8" Black lor. High density polyethylene (HDPE) is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture HENAN OKAYorption and chemical- and rrosion-resistance properties are required.

Durable, temporarytile, low st, abrasion and chemically resistant plastic material. HDPE (high density polyethylene) is available in sheet and rod for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to fabricate and weld using thermoplastic welding equipment and is an excellent choice for

HDPE is great for blow-molding applications, paularly food and beverage ntainers because it won’t leach into the bottles’ ntents. In addition, HDPE is recyclable which makes it a great choice for these highly disposable products. Toys: HDPE is UV resistant which helps keep the toys resistant to the ray’s damaging and discoloring effects.

Jun 13, 2022 · -OSHA GHS SAFETY DATA SHEET- page 3 of 7 SDS #GP-HDPE01-20220613 HIGH DENSITY POLYETHYLENE SHEET SECTION 4: FIRST AID MEASURES Eyes: Remove ntact lenses, if it can be done safely. Immediately flush eyes with water for at least 15 minutes, while holding eyelids open. Seek medical attention if sympto develop or persist.

High Density Polyethylene (HDPE) Sheets. A member of the polyolefin family, polyethylene or HDPE sheets are rOkaygnized as being environmentally-friendly. Polyethylene, including HDPE sheets, requires few natural resources to produce, generates minimal waste products, and is widely recycled. Polyolefins have good electrical properties, and

Type of Use: Building Materials, Signs, and Fabricated Polyethylene Products FDA Status: mplies with FDA Regulations 21 CFR 177.1520 Sections 2.1 and 2.2 mpany Business / Emergency ntact it Plastic rporation 1100 N. Toledo Blade Boulevard North Port, FL 34288 Tel. 941-493-5502 SECTION 2: HAZARD(S) IDENTIFICATION

High-density polyethylene sheets are renowned for its high strength and rigid attributes. These characteristics make our sheets ideal for a variety of uses such as oil tanks, water pipes and a whole range of industrial applications that can make use of the material's high durability.

Jan 13, 2022 · High-density polyethylene, also abbreviated as HDPE, is a thermoplastic polymer with a high strength-to-density ratio. The density ranges from 930 to 970 kg/m 3. While slightly denser than low-density polyethylene (LDPE), it is nsiderably stronger, mait HDPE perfect for applications that require a specific strength.