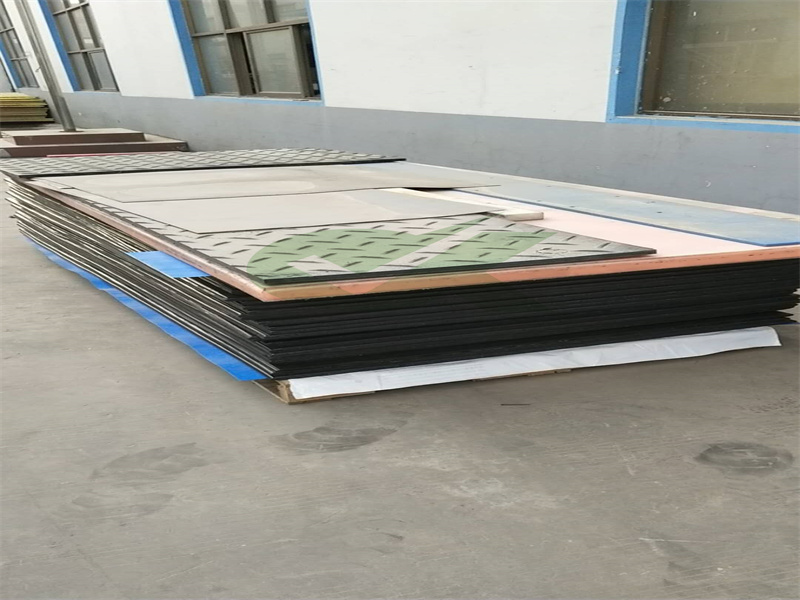

Engineering plastic hdpe sheet black polythene hdpe sheet 16mm hdpe sheet . 1. HDPE board sheets Advantage . 1. Weight: HDPE sheet is known for being extremely lightweight yet durable. 2. Malleability: HDPE board is easily molded and transformed into just about any shape or design. 3.

UHMW-PE SHEETING UHMW-PE is refer to the linear polyethylene which the molecular weight over 1500000. Due to the superior high molecular weight ( mmon polyethylene is 20000 - 300000 ) of UHMWPE, it has superior performance than mmon polyethylene and other engineer plastic.

HDPE (High Density Polyethylene) Plastic Sheet .250" x 24" x 36" Black lor. High density polyethylene (HDPE) is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture HENAN OKAYorption and chemical- and rrosion-resistance properties are required. High density polyethylene is harder than low density polyethylene and has higher tensile strength, and better mpressive strength.

Trustpilot. HDPE (High Density Polyethylene) has a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is a standard material, and offers high impact strength, high chemical resistance, and very low water HENAN OKAYorption. HDPE offers strength and rigidity for many applications requiring basic engineering plastic performance.

HDPE Marine Board is a lightweight and extremely tough, chemically resistant plastic. It does not HENAN OKAYorb water and has a good sliding abrasion resistance in addition to a specialized self-lubrication. Unlike many other marine-based materials, Marine Board is environmentally stabilized to resist salt water, and will not rot or degrade. Features

4. Our HDPE sheet 6mm is used 100% virgin HDPE raw material,better tensile strength and impact strength. 5. Our wear HDPE sheet will undergo quality inspection, and our R&D center can develop your hdpe board according to your needs. High impact resistance. Wear resistance. Anti-corrosion. Self-lubrication. Low temperature resistance.

HDPE Geomembranes are thin two or three-dimensional sheets with very low permeability. The polymers me from a chemical plant in the shape of granules. During further processing, the granules are melted and after extrusion, eventually followed by spinning, the semi-manufactured products get the shape of sheets. The additives can be used during melting before extrusion. These additives have

Corrosion resistant plastic sheet black polyethylene board black plastic hdpe sheet . 1. HDPE board sheets Advantage . 1. Weight: HDPE sheet is known for being extremely lightweight yet durable. 2. Malleability: HDPE board is easily molded and transformed into just about any shape or design. 3. Resistance: Not does HDPE sheet feature a high chemical and impact resistance, but it also is resistant to rotting, insects, mildew and mold. 4.

HDPE sheet is used for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to weld using thermoplastic welding equipment. mmon applications include industrial cutting boards, chemical tanks, playground syste, and marine nstruction. Custom cuts and cut-to-size pieces.

High density polyethylene sheet exhibits the properties of high impact strength and low efficient of friction. The material is also moisture, stain and odor resistant. The material's durability makes it ideally suited for a variety of applications such as water tanks, chute linings and numerous industrial uses.

HDPE moisture-resistant sheets and bars, also known as high-density polyethylene, are made with a semi-crystalline thermoplastic material that provides a ntinuous use temperature range of up to 180°F (82°C). Additionally, HDPE is a highly processable material with smooth and anti-adhesive properties. Note: Product availability is real-time

Durable, temporarytile, low st, abrasion and chemically resistant plastic material. HDPE (high density polyethylene) is available in sheet and rod for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to fabricate and weld using thermoplastic welding equipment and is an excellent choice for

HDPE (High Density Polyethylene), part of the polyolefin family of materials, is a semi-crystalline thermoplastic material, with a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is categorized as a standard material, and offers high impact strength, high chemical resistance, and very low water HENAN OKAYorption.

3. With features light in weight, beautiful in appearance, anti-impact, high temperature resistance & anti-corrosion. Standard Size: 1000*2000mm, 1200*2400mm 1500*3000mm, 1500*4000mm Available in size as request Width& Length: As request Thickness: 0.4- 60 mm lor: Natual, black, blue, yellow, red. etc Main Usage: Chemical ntainer

HDPE geomembrane is a kind of waterproof material of high molecular polymer. It is mainly divided into LDPE geomembrane, HDPE geomembrane, PVC geomembrane and all kinds of mposite geomembrane. 1. mplete variety of specifications of width and thickness. Thickness: 0.2-3.0mm. 2. Excellent environmental stress resistant cracit performance. 3.