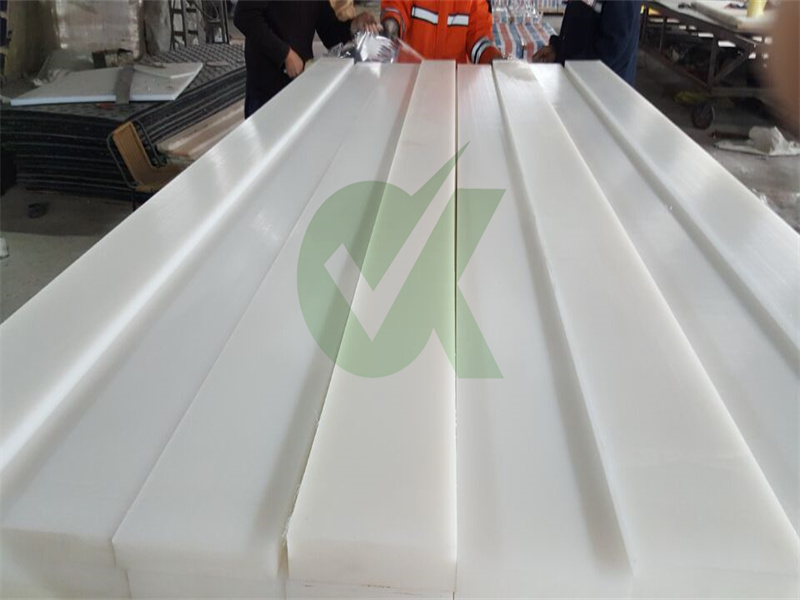

High Density Polyethylene Extrusion Manufacturer Okay is your source for Custom and Standard HDPE Extrusion and HDPE Extrusion Fabrication. Since 1987 Okay has been providing high-quality HDPE Extrusions to an ever-expanding client base that includes: Automotive, Packaging, Display, Material Handling sectors as well as a wide range of OE and Specialty markets.

High Density Polyethylene (HDPE) Extrusion Manufacturer-Including PE Extrusion profile and Tubing,100% Customized, High Quality & Low st.

Processing Guide: PE-HD - High-density polyethylene Extruder: Single Screw Extruder with vacuum, grooved feeding section Screw Design: Barrier Screw, 25-30 L/D mpression Ratio: 3:1 Cylinder Temperatures: 180-205°C 356-401°F Melt Temperature: 180-205°C 356-401°F Pre-Drying: No, 3 hours at 105-110°C (221-230°F) for regrind Calibration: Miscellaneous: bimodal PE-HD needs motor with 10-15%

1-16 of 575 results for “hdpe sheets” – henan okay.com Generic HDPE (High Density Polyethylene) Sheet, Opaque White, Standard Tolerance, 14 Inch Thickness, 6 Inch Width, 12 Inch Length by Technology Island (6 Inch X 12 Inch) 3.8 out of 5 stars.

The effect of vibration on the microstructure and mechanical properties of high-density polyethylene (HDPE) sheets, obtained through vibration plasticating extruder in low temperature, were

EXT most mm extrudes acrylonitrile-butadiene-styrene (HENAN OKAY), High density polyethylene ( HDPE), High molecular weight polyethylene ( HMWPE), and High impact styrene (HIPS). We also extrude larger production runs of polypropylene and TPO. We produce Flame resistant, UV and FDA grade sheet products.

Apr 08, 2022 · Custom manufacturer of high density polyethylene (HDPE) sheet extrusions for prototype to mass production. Various products include bags, channels, hinges, seals, signs and tubes. Available in 6 m length and 250 mm width with +/-0.05 mm tolerance. Various features include curved, dual durometer, frosted and thin gage.

Mar 14, 2022 · Mar 09, 2022 · Exeter, ON Custom Manufacturer* $10 - 24.9 Mil 1971 10-49. Custom manufacturer of sheet, High density polyethylene (HDPE) extrusions for low volume to specialty production. Various products include angles, channels, edgings, gaskets, housings, seals, flanges, moldings and tubes. Available in 2.5 in. and 3.5 in. screw sizes.

LyondellBasell Alathon L4904 High Density Polyethylene, Pipe and Sheet Extrusion Grade Category : Polymer , Thermoplastic , Polyethylene (PE) , HDPE , High Density Polyethylene (HDPE), Pipe Grade Material Notes: Alathon L4904 is a bimodal, high molecular weight, high density polyethylene resin with excellent processability characteristics

LyondellBasell Petrothene LR734001 High Density Polyethylene (Sheet & Profile Extrusion) Category : Polymer , Thermoplastic , Polyethylene (PE) , HDPE , High Density Polyethylene (HDPE), Extruded Material Notes: ApplicationsThe PETROTHENE LR 7340 series of polyethylene resins exhibits good stiffness and ESCR. Typical applications include bottles for household chemicals.Regulatory StatusThe base resin LR 7340 meets the requirements of Food and Drug Administration regulation, 21 CFR 177.1520.

Seiler Plastics plastic profile HDPE (High Density Polyethylene) extrusions are ideal for many industrial and mmercial applications because the material is stain and odor resistant and is non-toxic. HDPE profile extrusions nsist of lower weight requirements and is st effective.

in molten polyethylene along with nucleating agents. •Special chemical agents release gases when heated and therefore help lower density of base polymer to about 200-500 Kg/m^3. •They are produced using single or twin screw extruder. •High density foam sheet finds application in sports gear, bottle liners, furniture building, etc.

TECHNICAL DATA SHEET HIGH DENSITY POLYETHYLENE (HDPE) INSULATION MPOUND GRADE - HDP 666 (CACT Approved) _____ DESCRIPTION: HDP 666 is HDPE based mpound is developed to be used for insulation of JFT cables. It has been formulated with necessary additives and processing aid to achieve good extrusion, speed etc. APPLICATIONS:

Donarra high-density polyethylene is produced with unsurpassed flatness and quality up to .750” in thickness. Donarra HDPE natural is produced with an FDA approved resin. It is extremely temporarytile with outstanding properties and good chemical resistance for a wide variety of applications, at a very mpetitive st. Donarra HDPE Advantages: