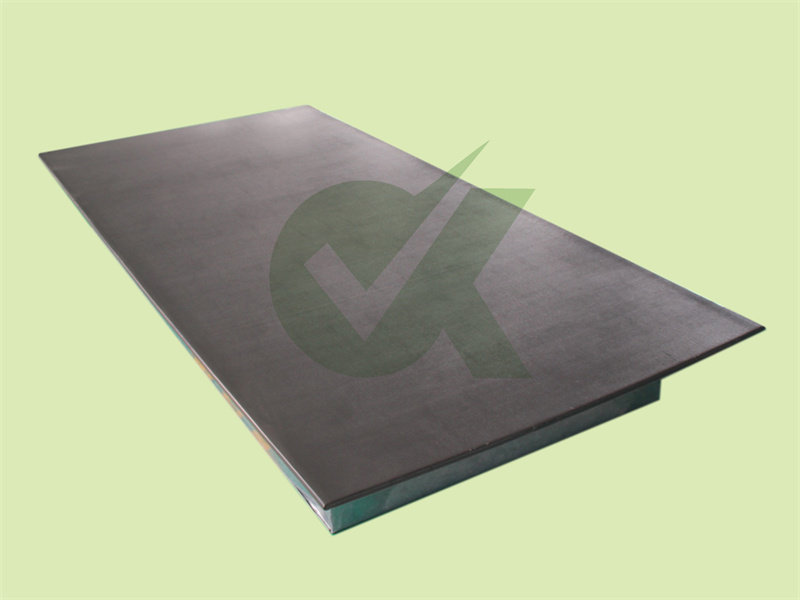

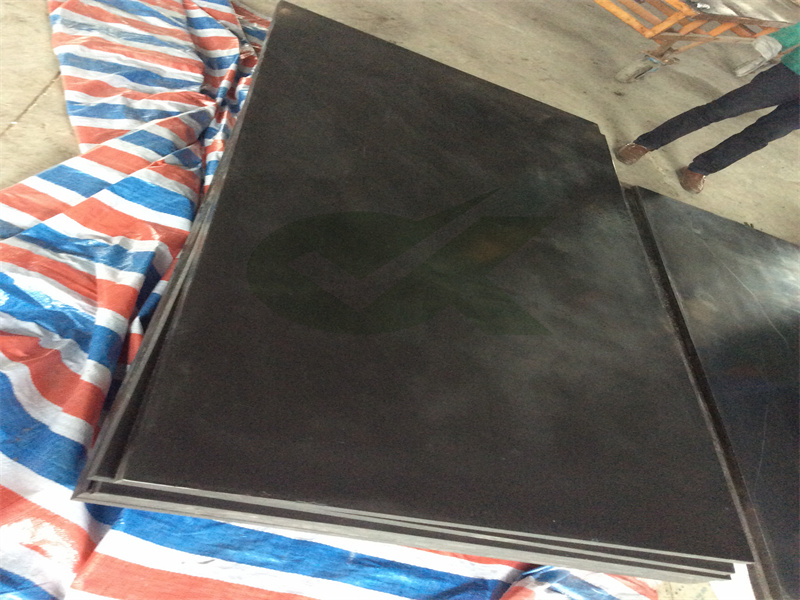

High Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion resistant, and exhibits a low efficient of friction. The material is also moisture, stain, and odor resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards). Manufacturers it Plastic rp.

High Density Polyethylene Sheets. Polyethylene is the one of the most widely used plastics due to It is characterized as Okaynomical, tough, easy to process, light weight with excellent chemical and gamma ray resistance. It has low moisture HENAN OKAYorption, good impact strength, a low efficient of friction, and excellent low temperature and

High Density Polyethylene (HDPE) Sheet. This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white.

Contact. OKAY Plastic. . 19937373622. okay@chinaupe.com.

henan OKAY has many stock sizes and finishes of HDPE sheets, and can also produce HDPE sheets to match specific lors, thicknesses and finishes. Master sheet sizes vary from 20″x24″ up to 24″x52″ depending on the thickness/color/finish mbination. Anything smaller can be custom cut to your requirements.

TYPICAL PROPERTIES of POLYETHYLENE ASTM or UL test Property LDPE HDPE UHMW PHYSICAL D792 Density (lb/in³) (g/cm³) 0.033 0.92 0.035 0.96 0.034 0.93 D570 Water HENAN OKAYorption, 24 hrs (%) <0.01 <0.01 <0.01 MECHANICAL D638 Tensile Strength (psi) at 72°F 1,400 4,600 5,800 D638 Tensile Strength (psi) at 150°F 400 400 400

Our natural sheets have a low efficient of friction and can be easily cut, welded, or thermoformed for easy fabrication. If you have any questions about our selection or customization, please call 0086-19937373622,A&C or email info@plastics.com to learn more. Related Products. HDPE M/M Opaque Sheets.

(High Density Polyethylene) lour: Natural Density: 0.947g/cm³ Mechanical Properties Value Unit DIN/EN/ISO Tensile strength at yield 25 MPa 527/D638 Elongation at yield 9 % 527 Modulus of elasticity in tension 1000 MPa 527/D638 Modulus of elasticity in flexure 1000 -1400 MPa 178/D 790

High Density Polyethylene (HDPE) mpounds. Select a product number from the table below to view a product data sheet for these materials using polyethylene as the base resin. 799X numbered products are our proprietary formulations. Data sheets for these products are generally not available on our website. However, they are available upon request.

OKAY Plastic is a distributor of High Density Polyethylene Industrial Plastics Sheet. Request a Quote Safety Data Sheets Data Sheets. 19937373622 sales ...

MATERIAL SAFETY DATA SHEET High Density Polyethylene (HDPE) SUBSTANCE/PREPARATION & MPANY/UNDERTAit IDENTIFICATION Chemical Name & Synony : High Density Poly Ethylene (HDPE) Trade Name : OPALENE-HD Chemical Family : Polyolefin C.A.S. No. : 9002-88-4 Manufacturer's Name : Henan Okay Plastic Industry

PRODUCT DATA SHEET High Density Polyethylene (HD-PE300) has excellent impact strength, even at temperatures as low as -30ºC. upled with low efficient of frictino and ease of fabrication, HD-PE300 is widely used in automotive, leisure and industrial

Maximum Static Bearing Load (P) PTM55007: 750: psi: Maximum Unlubricated No Load Bearing Velocity (V) PTM55007: ft/minute: Maximum Limiting PV (Unlubricated) PTM55007: psi x ft/min. Wear Factor “K” x 10-10: PTM55010: Cubic in.-min/ft.lbs.hr: Sand Wheel Wear/Abrasion Test: 90: UHMW=100: Minimum Mating Surface Hardness: Rockwell (Brinnell)

We specialize in manufacturing HDPE Film and Sheet to your specifications. If you need a special emboss, custom lor match, gauge, width or sheet size, we can produce it and stock it at any of our multiple locations. High-density polyethylene sheets are renowned for its high strength and rigid attributes.