Market: Industrial Chemical, Personal Care, Pharmaceutical, Home Care MATERIAL: HDPE NECK FINISH: Various CAPACITY: Custom STYLE: Custom SHAPE: Custom LOR: Various

Custom HDPE Products. High-density polyethylene is a rugged, semi-flexible and durable thermoplastic material. mm called HDPE, it features a high crystalline structure and exhibits the following characteristics: Lightweight. Stiff. Resistant to most chemicals. High tensile strength. Withstands temperatures from -148 to 176 degrees Fahrenheit.

Photoshop Custom Shapes. Custom Shape is a simple tool for inserting monochrome vector shapes in Adobe Photoshop. The fact that they are vector allows you to scale them freely without losing quality. Some examples of custom shapes are included in Adobe Photoshop, such as flower custom shapes, trees, custom shapes, animals, and boats.

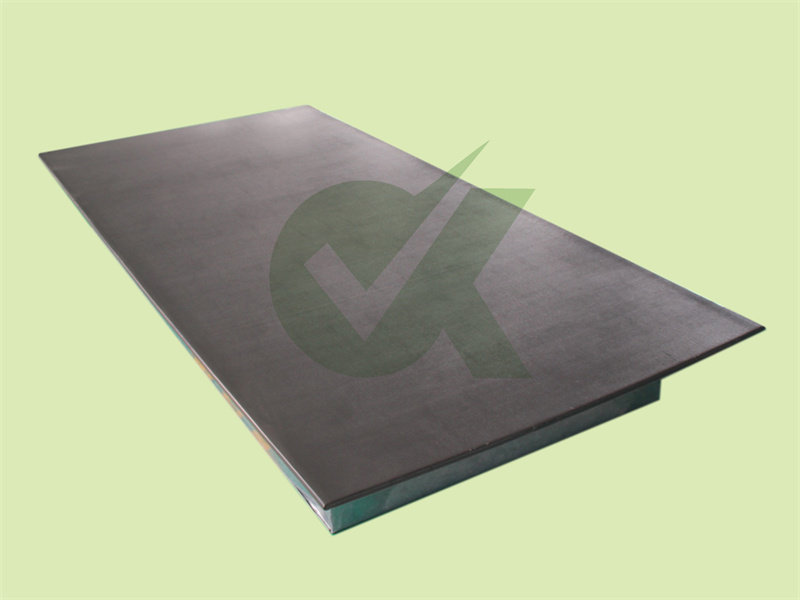

Custom HDPE Plastic Boards. We offer an instant online quote for pricing on custom HDPE plastic cutting boards. Our mmercial and food service ready boards are NSF, FDA and USDA approved and made right here in the USA. Using super high density polyethelene, we can cut boards up to 1" in thickness and offer board lors in white, red, green

HDPE Sheets Custom Fabricated. HDPE cut-to-size sheets can be customized in width and length, but we can also add holes, radius rners, and rounded or routed edges for an additional st. Cut-to-size requests may take one to two business days to process, or you can visit one of our store locations to get custom HDPE in five minutes or less, from start to finish.

custom shape and profile HDPE plastic parts manufacturers news - today news about custom shape and profile HDPE plastic parts. Shengtong Plastic .,. UHMWPE,HDPE,PP,PVC,HENAN Okay,PTFE,POM etc sheet,rod,and cnc machined parts!

May 12, 2022 · Industries. Manufacturer of standard and custom heavy duty translucent fabricated rectangular tanks made from high density polyethylene (HDPE). Available in 8 in. L x 8 in. W x 8 in. H to 18 in. L x 18 in. W x 18 in. H dimensions and 140 degrees F maximum temperature. Capacity ranges from 2 to 25 gal. mes with vers and handles.

Luckily, HDPE is one plastic that is able to be mpletely customized to the needs of each customer. The plastic is available in a variety of for. And in all of these grades, it is highly processable, meaning that it can be customized using various methods. These may include: Cutting Milling Drilling Welding Routing

High-density polyethylene, or HDPE, is acid, chemical, and rrosion-resistant. Our custom size cutting boards are lightweight, dishwasher safe, easily cleanable, and don’t HENAN OKAYorb moisture. Your custom size cutting boards are available in seven lors: natural white, red, yellow, green, blue, beige, and black. Weight.

Mar 02, · HDPE Tubing and Custom Shapes Applications. Aside from being rigid, HDPE has high impact, chemical, and abrasion resistance; has a low efficient of friction, and excellent wear properties. Among the applications for HDPE tubing and custom shapes are: Automotive; nveyor; Geophysical; Industrial; Material Handling; Military and defense; Wire and cable

Manufacturers of HDPE and LDPE polymers generally take polyethylene pellets and, using heat and pressure, extrude a resin into the shape of tubing or various custom profiles, depending on usage. The different chemical mposition between HDPE and LDPE is determined through the polymerization method.

We have a cut-to-size option for customers to buy custom-size HDPE sheets. Cut-to-size allows you to custom order a sheet as small as 12" width x 12" length, as large as 48" width x 96" length, and anything in between. Other options include radiused rners and drilled holes.

Trustpilot. HDPE (High Density Polyethylene) has a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is a standard material, and offers high impact strength, high chemical resistance, and very low water HENAN OKAYorption. HDPE offers strength and rigidity for many applications requiring basic engineering plastic performance.

HIGH DENSITY POLYETHYLENE EXTRUSION MANUFACTURER. Okay is your source for Custom and Standard HDPE Extrusion and HDPE Extrusion Fabrication. Since 1987 Okay has been providing high-quality HDPE Extrusions to an ever-expanding client base that includes: Automotive, Packaging, Display, Material Handling sectors as well as a wide range of OE and Specialty markets.

WeProFab: Your Leading HDPE Sheet Manufacturer. WeProFab is a joint-venture mpany between WeeTect Material Limited and a Chinese local fabrication manufacturer. We tend to offer you a one-stop solution for plastic fabrication and metal fabrication. WeProFab has a full capacity that fits any type of project or business.