• Australian made from 100% recycled plastic, including farm soft plastics • Easy to use and affix to fencing panels with Tek screws, timber screws or cable ties. • Chemically inert • Recyclable. Poly Sheet 1.m Thick Specifications: 600mm x 10m x 1.m (Black) 600mm x 30m x 1.m (Black) Poly Sheet m Thick Specifications:

Product Information Standard sheet size tolerance is 2400+40/-0mm x 1200+20/-0mm, sheet squareness tolerance is within 5mm. Sheet thickness tolerance is ±5% or +/-1mm, whichever is greater. Sheet thickness can vary within the tolerance from rner to rner within one sheet. General guidelines regarding thermal expansion/contraction:

OKAY BoatBoard HDPE is a premium grade High Density Polyethylene weather proof HDPE used primarily for marine applications. With its superior flatness and low inherent stress, OKAY BoatBoard HDPE sets the standard for fabrication ease among weather resistant sheet products for outdoor applications. This HDPE Boatboard includes marine

Builders Film is a Polyethylene Sheet (PE) manufactured using high-quality recycled low-density polyethylene resins. Damp Proof Membrane 200um supplied in a 4 x 50m roll. This high-impact membrane is ideal for landscaping, nstruction use and general protection onsite. Specifications. Applications.

HDPE is available in Natural 2000mm x 1000mm sheets for thicknesses 1.5mm to 15mm and in black or Natural 3000mm x 1500mm sheets for thicknesses m to 30m. AVAILABLE ON REQUEST PLEASE ALLOW 1-2 WORit DAYS

The chemical and the crack resistance are optimised in mparison to the standard high density Polyethylene, and is therefore suitable for applications subject to ntinuous shocks. The operating temperature of UHMWPE is from -150°C to +90°C. The OMEGA- ULTRA UHMWPE is defined as polyethylene whose molecular weight is 3,100,000 or higher.

LDPE Technical Data Sheet General Applications Options (High Density & Low Density Polyethylene) These materials have excellent impact strength and can be easily formed and machined using nventional equipment. They are available in a range of sheet sizes for everyday applications.

Polystone UHMWPE Sheet has a minimal molecular weight of 9 million, which has a positive impact on material performance in an abrasive environment. Polystone UHMWPE Sheet is available in various grades of material depending on the application requirements. Key Benefits: Very light weight; Extremely tough; Chemically resistant; Excellent wear

High Density Polyethylene (HDPE) is manufactured from the semi-crystalline polyethylene (PE) family. HDPE is available in various grades depending on the application requirements. The information above is for quick reference . Please refer to technical data sheet in the product downloads tab.

UHMWPE. UHMWPE ultra high molecular weight polyethylene (PE1000) is frequently used in high-wear applications, from wear strips under nveyors to guide rails in bottling plants, or scraper blades on road rollers. UHMWPE sheets are used for lining bulk storage hoppers where low-friction, anti-stick and abrasion-resistant properties solve feed

HDPE Sheets. We extrude a range of Polyethylene (PE) sheet suited for fabrication, thermoforming and building nstruction applications. HDPE (High Density Polyethylene) sheet is the most widely used thermoplastic polymer for fabricated parts due to its excellent chemical and impact resistance.

HDPE Sheets PE100 - Full Sheets, Cut to Size, Fabrication, TankHDPEgh Density Polyethylene (HDPE) also known as PE100 is a rigid high impact strength sheet. Black polyethylene shee Tel: 8619937373622

HDPE high density polyethylene (PE300) has excellent impact strength, even at temperatures as low as -30ºC. upled with low efficient of friction and ease of fabrication, HDPE high density polyethylene is widely used in automotive, leisure and industrial applications and is paularly suitable for the fabrication of tanks, silos, hoppers etc.

OKAY rigid PVC sheet is world renowned for quality and durability. Polyvinyl chloride (PVC) is an amorphous thermoplastic with a service temperature range from 0 degrees C to +60 degress celsius. It displays good chemical properties, fulfills various standards in respect to low flammability and is highly temporarytile when processing.

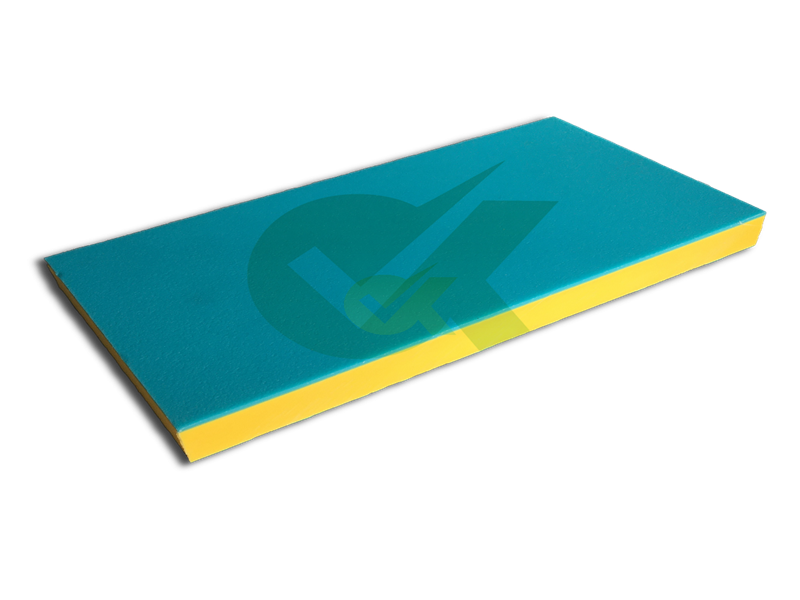

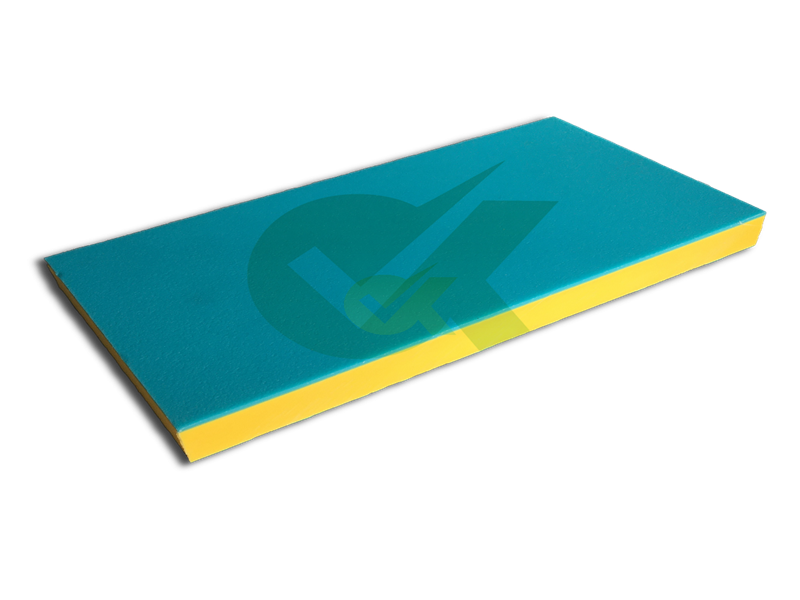

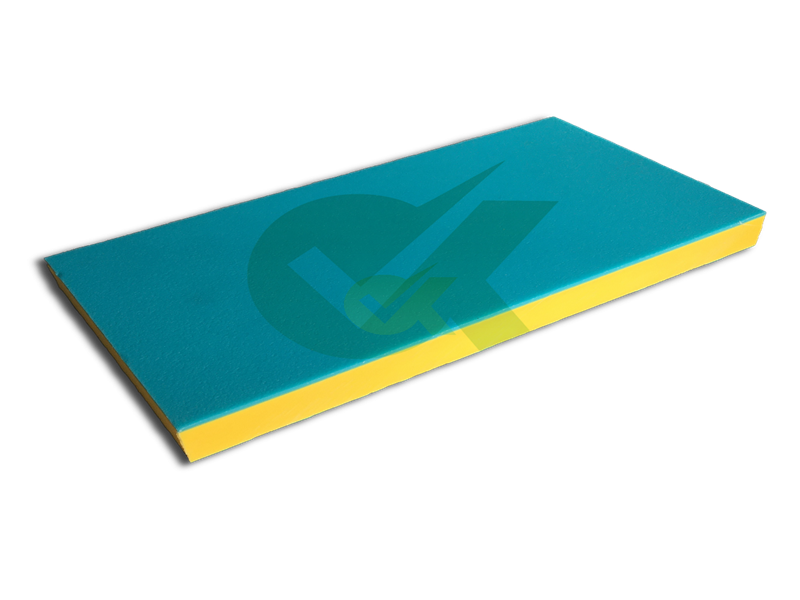

Polyethylene is similar to EVA; however, it is a firmer product with a better mpression set and greater resistance to heat. Importantly, PE foam is more st-effective than EVA. It’s also available in thicker sheets and a range of density from 30 to 250 kg/m3. Polyethylene Foam is formed in a mould, resulting in a sheet of foam known as a bun.