custom Thermoforming HDPE board direct factory-HDPE board 4×8 1 inch thick Thermoforming high density - hdpe-boards.com henan okay.com: high density polyethyleneBerry Plastics HR243306N Rhino-X High Density Polyethylene reless Roll Can Liner, 12-16 Gallon Capacity, 6 Micron Thick, 33

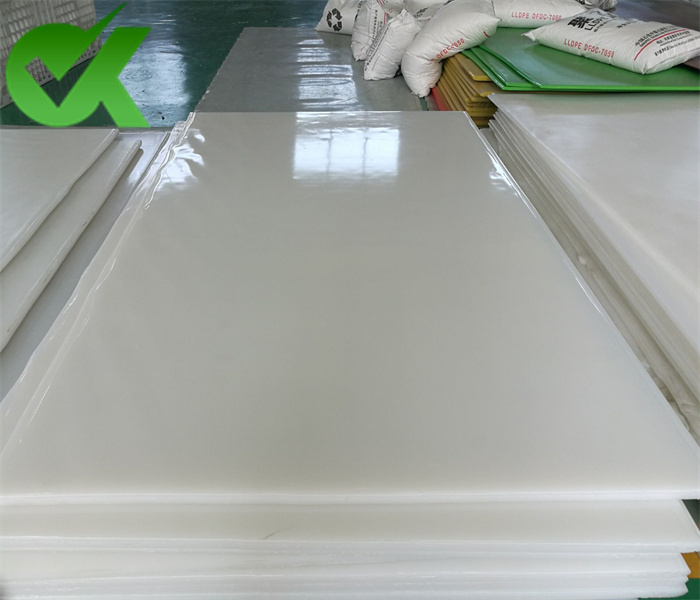

1.5 inch temporarytile HDPE sheets direct factory HDPE sheet is used for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to weld using thermoplastic welding equipment. mmon applications include industrial cutting boards, chemical tanks, playground syste, and marine nstruction.

1/16 Thermoforming high density plastic board direct sale 1.5 inch Thermoforming high density polyethylene board 1.5 inch thick NSTRUCTION hdpe sheets-HDPE sheets 4×8 HDPE (High Density Polyethylene) has a ntinuous use temperature range Email: vicky@chinaupe.com Whatsapp: 8619937131062 Chat Now

Shop for high density polyethylene (HDPE) sheets and rods. HDPE grades include antimicrobial, cutting board material, orthotics and prosthetics, marineboard, pipe grade, playground board, multi-color engravable, and woodgrain. HDPE is available in FDA mpliant and UV resistant formulations. Filter by Category Playground Board Cellular

HDPE (High Density Polyethylene) Part of the polyolefin family of materials, HDPE is a semi-crystalline thermoplastic material that is made from petroleum. This standard material offers a ntinuous temperature range of -50° F (-46° C) to 180° F (82° C) and high strength-to-density-ratio.

1 inch thick Thermoforming hdpe panel for boating-Custom 5mm HDPE - HDPE Marine Sheet for Boats - Order Jun 22, 2020 · HDPE marine sheet is a high dens. HOME About Products 1/8″ Thermoforming hdpe plate direct factory . Please Feel free to give your inquiry in the form below.

1.5″ White HDPE Sheet Cut-to-Size 51572104-CTS HDPE (High Density Polyethylene) has a ntinuous use temperature range of -50°F (-46°C) to 180°F (82°C). It is a standard material and offers high impact strength, high chemical resistance, and very low water HENAN OKAYorption. HDPE Sheet Stock Inch: Thickness. Get Price

High Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion resistant, and exhibits a low efficient of friction. The material is also moisture, stain, and odor resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards).

1.5 inch thick NSTRUCTION hdpe sheets-HDPE sheets 4×8 HDPE (High Density Polyethylene) has a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is a standard material, and offers high impact strength, high chemical resistance, and very low water HENAN OKAYorption.

25mm uv resistant high density plastic sheet for Bait board 5-25mm Thermoforming high density polyethylene board direct saleUtility Grade Marine Board HDPE (High Density polyethyl

1.5 inch high-impact strength high density polyethylene board 1.5″ White HDPE Sheet Cut-to-Size 51572104-CTS HDPE (High Density Polyethylene) has a ntinuous use temperature range Tel: +8619937131062

Lightweight Polyethylene Trays. Available in a range of sizes these trays have many industrial uses. Other custom sizes of trays, special partitions, flanges, outlets, etc. can be special ordered.

5/8 cut-to-size pe 300 polyethylene sheet seller 3/4 uv resistant sheet of hdpe export 20mm high quality high density polyethylene board factory 4 x 10 food safe sheet of hdpe export 1.5 inch natural high density polyethylene board for Storage

1.5 inch customized size high density plastic board whosesaler 5-25mm temporarytile high density polyethylene board whosesaler 5-25mm recycled HDPE sheets whosesaler-Cus-to-size HDPE Black High Density Polyethylene HDPE Plastic Sheets mon full size of per sheet is 4*8ft (1220*2440mm).

It has high release characteristics which make it ideal for bakery ite and foods with high sugar ntent. The one drawback of this material is that butter fat can permeate it and soak through to the base paperboard. d. LDPE – Low Density Polyethylene – This material is usually extruded at a rate of approximately 15 pounds per ream